Stainless Steel V Shaped Pattern Bar Formers

These triangular pattern bar formers are made from high quality 3mm thick Stainless Steel so they will stand up to the high temperatures of fusing and give you years of use without warping or going out of shape. The V shape is a perfect 90 degree angle ensuring that your pieces will form a nice square when laying 4 cut pieces together. The two ends have been designed with two grooves so you can use metal rods to create a flow bar.

They are available in 3 different sizes and can be bought with or without the optional support rods.

The sides of the V are approx 6cm deep and the ends are 2.5cm higher than the former.

This is the perfect way to make unique pattern bars which can then be incorporated into other projects.

Simple to Use

The former needs to be lined with fibre paper to stop the glass sticking to it. We recommend using the Bullseye 1.6mm thick fibre paper. Cut 2 squares of fibre paper that are 6cm square, then cut each square into triangles, put one triangle into each end of the former. Now cut a piece of fibre paper that is the length of your former and 14cm wide - making the strip wider than the former prevents any accidental spillage of glass onto the former. Fold this in half lengthwise and put it into the former making sure it fits nice and tight, if you make a nice sharp fold it will help define the point on your triangle. Now slot the other 2 triangles into each end of the former, this double layer at the ends helps stop any glass leaking between the fibre paper. To help with clean up and minimise cold work you can spray Boron Nitrade on the fibre paper at this point but make sure it is dry before you put your glass in.

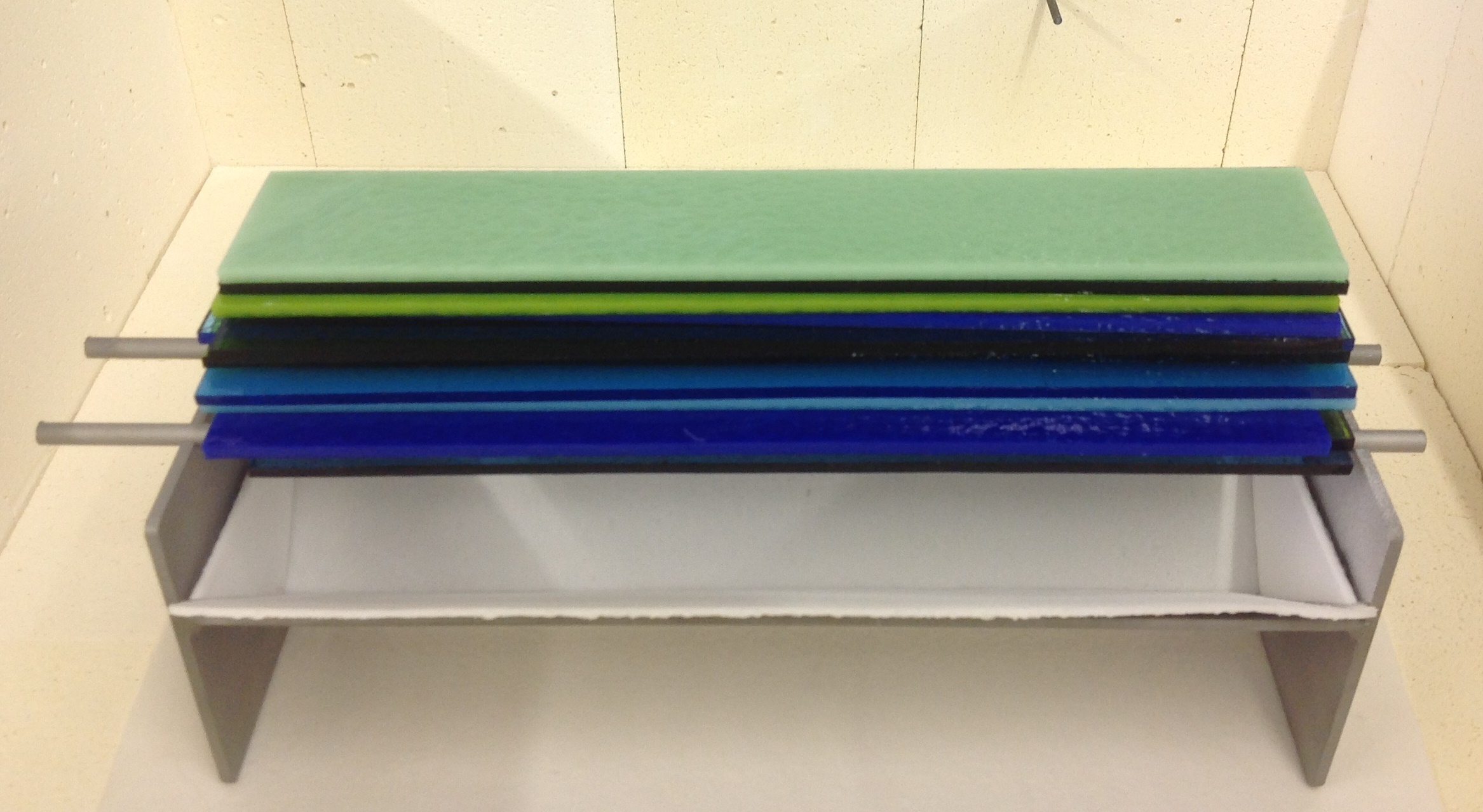

Now you simply fill the former with glass of your choice. You can use long strips the length of the bar to give you a repetitive pattern, or you can use frit or scrap glass for a more organic bar. When cold, clean off any fibre paper, slice up and they are ready to use in your project.

Optional Rods for Flow

Instead of putting the glass directly in the V Former you can lay the rods across the top of the former in the grooves and lay your glass on the rods. Keep the glass about 1cm in from the end of the former so it doesn't flow over the ends. When the glass heats up it flows through and around the rods giving a lovely flow pattern to the glass. Prepare the former as above. There is no need to coat the rods with any kind of seperator as this will end up in your glass. Most of the glass left on the rods will crack off as the rods cool down, this won't affect your melt but you will have some fine shards of glass to clear up in the kiln. Any remaining glass on the rods can usually be knocked off.

Firing

The formers can be put on a shelf or on the kiln floor. When using the rods we usually place a piece of fibre paper under the former just in case of overflow.

All kilns fire differently so we can't give you a definitive firing schedule but when we are placing the glass directly in the V former we fuse it on our standard full fuse schedule and anneal for 4 hours. When using the flow method with the bars you need a higher temperature for the glass to flow so we go to 829c (1525F).

Annealing times will depend on the amount of glass used but if the former is full then we anneal for 4 hours.

Maximum glass weights

20cm - 832g

25cm - 1040g

30cm - 1250g

35cm - 1460g